FDA’s New QMSR Rule for 2026: What Medical Device Manufacturers Must Do Now

Life Sciences Growth in 2025 – Why Your QA and Validation Teams Need to Scale Now

July 21, 2025

FDA QMSR Final Rule 2024: ISO 13485 Transition & Compliance Guide for Medical Device Manufacturers

August 12, 2025A new wrinkle in the regulatory environment for medical device manufacturers who market their devices in the USA is now looming on the near horizon.

In just six months, on 2 February 2026, the FDA’s Quality Management System Regulation (QMSR) goes into effect!

QMSR Replaces QSR with ISO 13485:2016 Alignment

It’s a major change in the way FDA defines its requirements for current Good Manufacturing Practice. The existing Quality System Regulation (QSR), in place since 1996 under as 21 CFR part 820, will be revised to incorporate by reference the requirements of international standard ISO 13485:2016. Most of the current content of 21 CFR 820 will no longer exist, with some exceptions, making ISO 13485:2016 the new centerpiece of the FDA’s QMSR.

By aligning the QMSR with ISO 13485:2016, the FDA aims to modernize, harmonize, and simplify global market access, while improving quality management practices across medical devices, IVDs, and combination products. The goal? To streamline global compliance by aligning with an established international standard.

Final Rule and FDA Resources

The Final Rule was published in the Federal Register of the United States Government on February 2, 2024, providing for a two-year transition period. Below are some resources:

- Final Rule revising 21 CFR 820 to incorporate ISO 13485:2016 by reference and establishing the QMSR

- The FDA’s Frequently Asked Questions regarding the QMSR and the Final Rule

What This Means for U.S.-Only Medical Device Manufacturers

As Dorothy in The Wizard of Oz observed, “Toto, I have a feeling we’re not in Kansas anymore.”

For many U.S.-based medical device manufacturers, especially those who only market domestically, QMSR represents a major shift. Companies will need to closely review ISO 13485 and update their QMS documentation, along with the related processes and practices to ensure compliance that their system meets the expectations of the QMSR.

Key differences include:

- Risk management and a risk-based approach to QMS processes

- A focus on competency, not just training

- More prescriptive requirements for certain processes such as Management Review and the evaluation and control of suppliers

It is critical for manufacturers who do not have an ISO 13485:2016 certified QMS to start working on evaluation of current gaps, action planning, and implementation if this activity hasn’t begun already.

Even ISO 13485-Certified Companies Aren’t Off the Hook

For manufacturers already certified to ISO 13485:2016, don’t assume you’re fully covered. The new QMSR retains and reinforces some of the requirements of the previous QSR that are additional to ISO 13485. These should be carefully reviewed for compliance and addressed with appropriate actions

Examples from the revised 21 CFR part 820 include the following:

820.10 Requirements for a quality management system

- Applicable regulatory requirements, including reference to 21 CFR parts 830 (UDI), 821 (Traceability), 803 (Reporting to regulatory authorities), and 806 (Advisory Notices)

- Design and Development – Class II and Class III devices and some Class I devices

820.35 Control of Records, including complaint records, service records, and UDI

820.45 Device labeling and packaging controls

QMSR Compliance: What You Should Be Doing Now

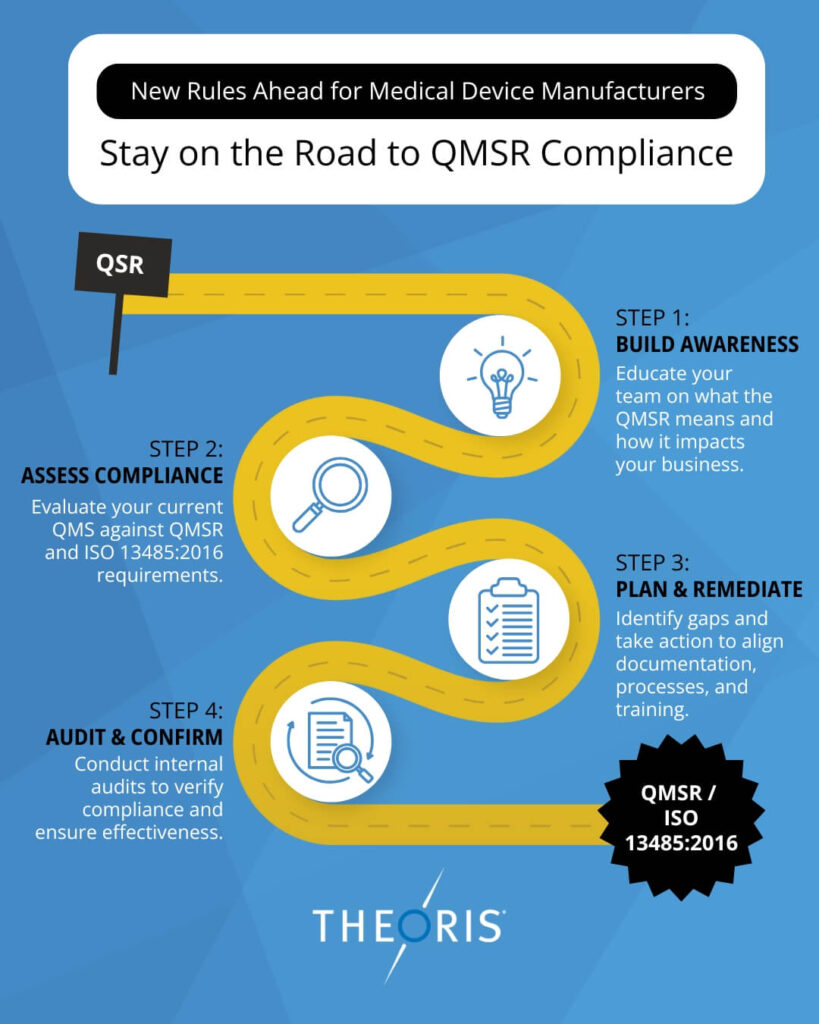

With the clock ticking, manufacturers of medical devices intended for marketing in the United States should be doing some form of the following activities without delay:

- Increasing the organization’s knowledge and awareness of the QMSR

- Evaluating current compliance status relative to the QMSR requirements

- Planning and carrying out actions deemed necessary for remediation

- Auditing to confirm status of compliance and effectiveness of actions taken

These tasks may take 3 – 6 months or more, depending on the size and complexity of the company’s operations, the structure and focus of its current QMS, and the mix of internal and external resources that may be applied to this work.

How Theoris Can Help with QMSR Readiness

- Assess Your Current QMS. Conduct a Gap Assessment of your existing Quality Management System to identify gaps in compliance with the QMSR requirements and where opportunities for improvement are possible.

- Update QMS Documentation and Processes. Provide remediation support for the revision of QMS documents and actual practices, including procedures, work instructions, and records, in accordance with QMSR and ISO 13485:2016 and any related regulatory requirements referenced by the QMSR. Support the implementation of risk management approaches as required by the QMSR.

- Knowledge Building. Provide training and educational sessions for your organization on the QMSR and the implications for the affected processes within the Company.

- Internal Audits. Conduct internal audits to verify compliance, document any residual nonconformities, and identify any opportunities for improvement in the revised QMS.

The Countdown to QMSR Is On…Let’s Get You Ready

If you’re unsure how these changes affect your organization or where to begin, Theoris can help. Contact us to schedule a consultation and take the first step toward QMSR compliance.

About the Author

Mike Wolf, CMDA, CQA, RAC

Director of Client Services at Theoris

Mike is a seasoned expert in Regulatory Affairs and Quality Management Systems, guiding life sciences companies—from startups to global enterprises—through audits, FDA readiness, and compliance with national and international standards. He holds certifications as a Medical Device Auditor (CMDA), Quality Auditor (CQA), and Regulatory Affairs Certificate (RAC Emeritus).